Grain Direction In Sheet Metal Bending

The grain direction created in the direction the sheet is rolled at the mill runs the length of the full sheet.

Grain direction in sheet metal bending. Bending metal against the grain or perpendicular to the grain is a common way to prevent material failure or cracking. You must pay careful attention to grain or rolling direction when bending high strength metals especially when trying to achieve a small inside bend radius. Whereas bending parallel to rolling direction can lead to cracks because of destruction in grain structure. That has negligible impact on part strength.

A metal s grain direction is usually only a factor when bending however. Bends that run perpendicular to the material s natural grain require slightly more pressure than those running parallel to the grain. This micrograin impacts the design in terms of strength and appearance. You can see it on a new piece of sheet metal by noticing the direction of visible lines running through it.

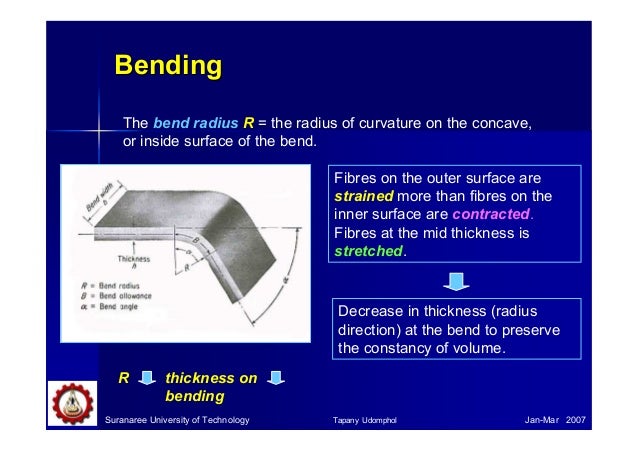

Applying this to metal bending be it plate bending press braking or any other type of metal forming consideration must be given to the grain direction before any process is carried out. When the sheet is made its particles become elongated in the direction of rolling. As a general rule the grain line must run perpendicular to the bend to avoid the potential for cracking or fracture. This occurs because bending along the grain allows for separation of the grain boundaries.

The raw sheet has a natural micrograin direction that runs parallel to the 144 in. Working with grain direction. Once the crystallites are elongated they appear as the grain that we see in cold rolled steel. Bending with the grain or parallel to the grain direction can be a contributor to material failure as bending along the grain allows for separation of the grain boundaries.

During sheet metal processing rolling operation material grains are arranged in the direction of rolling. The grain direction is in the rolling direction of the sheet as it was being manufactured. The grain direction is established during the metal rolling process. This is because sharper or tighter bends can be made across the grain without cracking.

Bending with the grain gives a different result than bending against it. In the example above perhaps were using a certain type of steel and specific bend radius whereby we need to be careful to ensure the sheet metal does not crack due to bending. We can manually control the grain direction of the metal in the flat pattern and subsequently how the bounding box is oriented to address these concerns. When sheetmetal is bend perpendicular to rolling direction grain rearranges.

In addition the grain direction needs to be considered when the bend radius is less than twice the thickness depending on the material and its hardness.