General Tolerance Table For Sheet Metal

For edge to edge hole to hole edge to hole tolerances shall be taken from column a.

General tolerance table for sheet metal. Variations on dimensions without tolerance values are according to iso 2768. This chart shows suggested tolerances. Iso 286 table shaft tolerances calculator. The information within this table is based on tertiary sources original research.

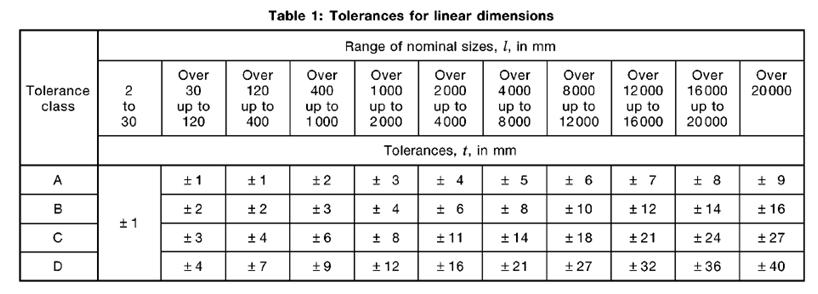

Over 6 to 30 incl. All tolerance limits are given in mm. General dimensional tolerances for parts formed by press working from sheet metal basic size step grades g rad ea b c over 1000 to 2000 incl. Over 30 to 120 incl.

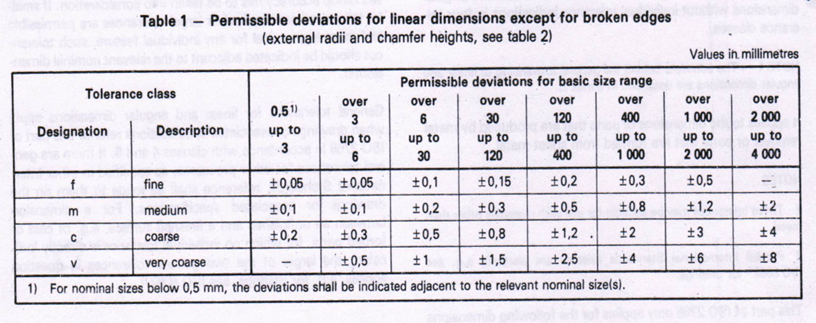

Sheet metal tolerance table subject. International tolerance grades. For sheet metal parts iso 2768 mk is used. Sheet metal tol tolerance table description.

General tolerances to din iso 2768. Over 400 to 1000 incl. In the above example m and k has defined the tolerance class. July 3 2018 by admin no comment s california dfm engineering metal stamping tooling california datum dimensions engineering gd t metal stamping stamped parts tolerances.

Tighter tolerances are possible for certain circumstances but not others. The latest din standard sheet version applies to all parts made to din standards. The main thing to be considered for selection of sheet metal tolerance is not just the linear dimension as like is 2102 the reference from where to where the dimension take plays a vital role. General tolerances part 2.

General tolerance iso 2768 does not specify where to use these tolerances. Sheet metal tolerances author. Uncontrolled dimensions contain two different categories of tolerances. Geometrical tolerances for features without individual tolerance indications.

1 all manufacturing tolerances used up to that point such as laser cutting tolerances welding tolerances and more 2 all bend tolerances for the entire part added together we call this an uncontrolled dimensions because there are additional tolerances to consider. Iso 286 table hole tolerances calculator. General tolerance iso 2768 does not specify where to use these tolerances. General dimensional tolerance of blanking unit mm 1.

1989 general tolerances part 2. Table 3 1 shown the unspecified sheet metal tolerance. Over 120 to 400 incl. Below are dimensions and tolerances typical of stamped metal components.

1985 technical drawings fundamental toleran cing principle. 6 or less note grade a b and c are equal to tolerance grade f m and c of jis b 0405 respectively. Variations on dimensions without tolerance values are according to din iso 2768 mk. And for machined components iso 2768 fh can be used.

And for machined components iso 2768 fh can be used. For sheet metal parts iso 2768 mk is used. General tolerances for linear and angular dimensions din iso 2768 t1 linear dimensions. Of course exceptions apply.

Iso 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for. 4 general tolerances 4 1 linear dimensions general tolerances for linear dimensions are given in tables 1 and 2.