Galvanized Corrugated Sheet Manufacturing Environmental Impact

Corrugated sheet intended use of the product no use is specified name address and telephone of the responsible party company.

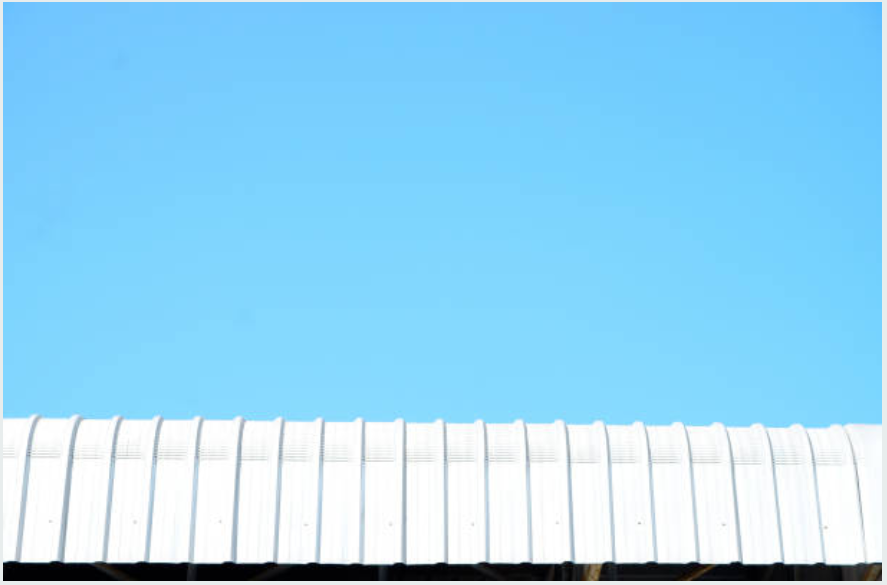

Galvanized corrugated sheet manufacturing environmental impact. The environmental impact assessment was carried out based on the life cycle assessment framework by the use of recipe 2016 method which was applicable on a global scale to evaluate the environmental impact of galvanized sheet production. Corrugated galvanized metal is great for wet areas because the material will not rust even after years of being sprayed with water. The 100 recyclability of hot dip galvanized steel is a great benefit to minimizing environmental impact but it is only half of the story. It s also very thin as you can see from the bird s eye view of an outdoor shower here.

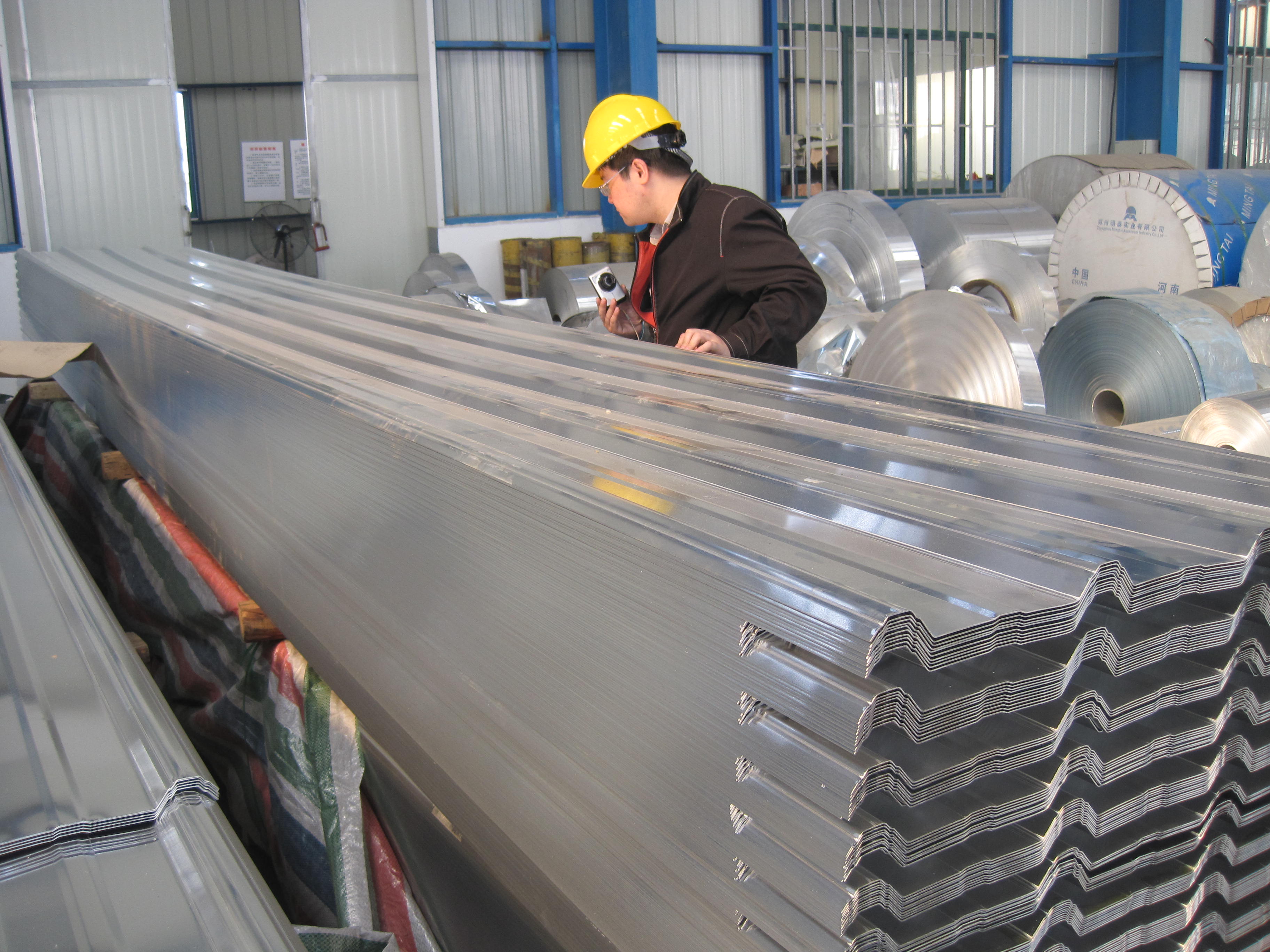

Steel comes in at one end and the finished galvanized product goes out at the other. There is a good spread of galvanizing plants across the uk and ireland and steel does not have to travel great distances to a nearby galvanizing plant keeping transport costs and environmental impacts as low as possible. Identification product identifier product form. Recycling rate and reclamation rate.

Corrugated galvanized sheet corrugated galvanised iron cgi sheets pressure steel sheet corrugated utility gauge galvanized steel roof panel corrugated metal roofing sheets manufacturing plant detailed project report profile business plan industry trends market research survey manufacturing. 05 26 2015 date of issue. Corrugated sheet safety data sheet revision date. Methods of uncertainty analysis and sensitivity analysis were adopted to provide credible support.