Fundamental Studies On The Incremental Sheet Metal Forming Technique

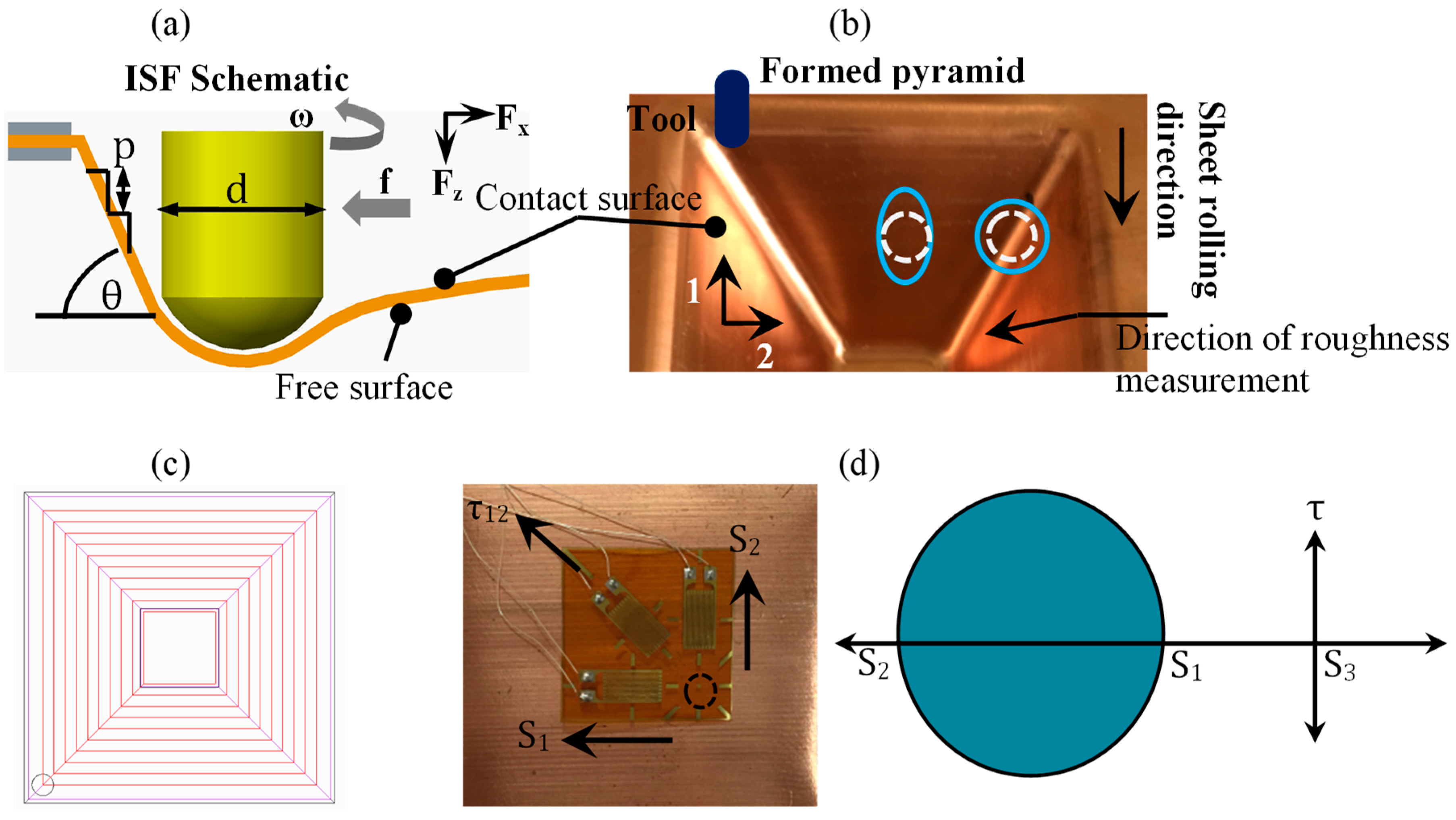

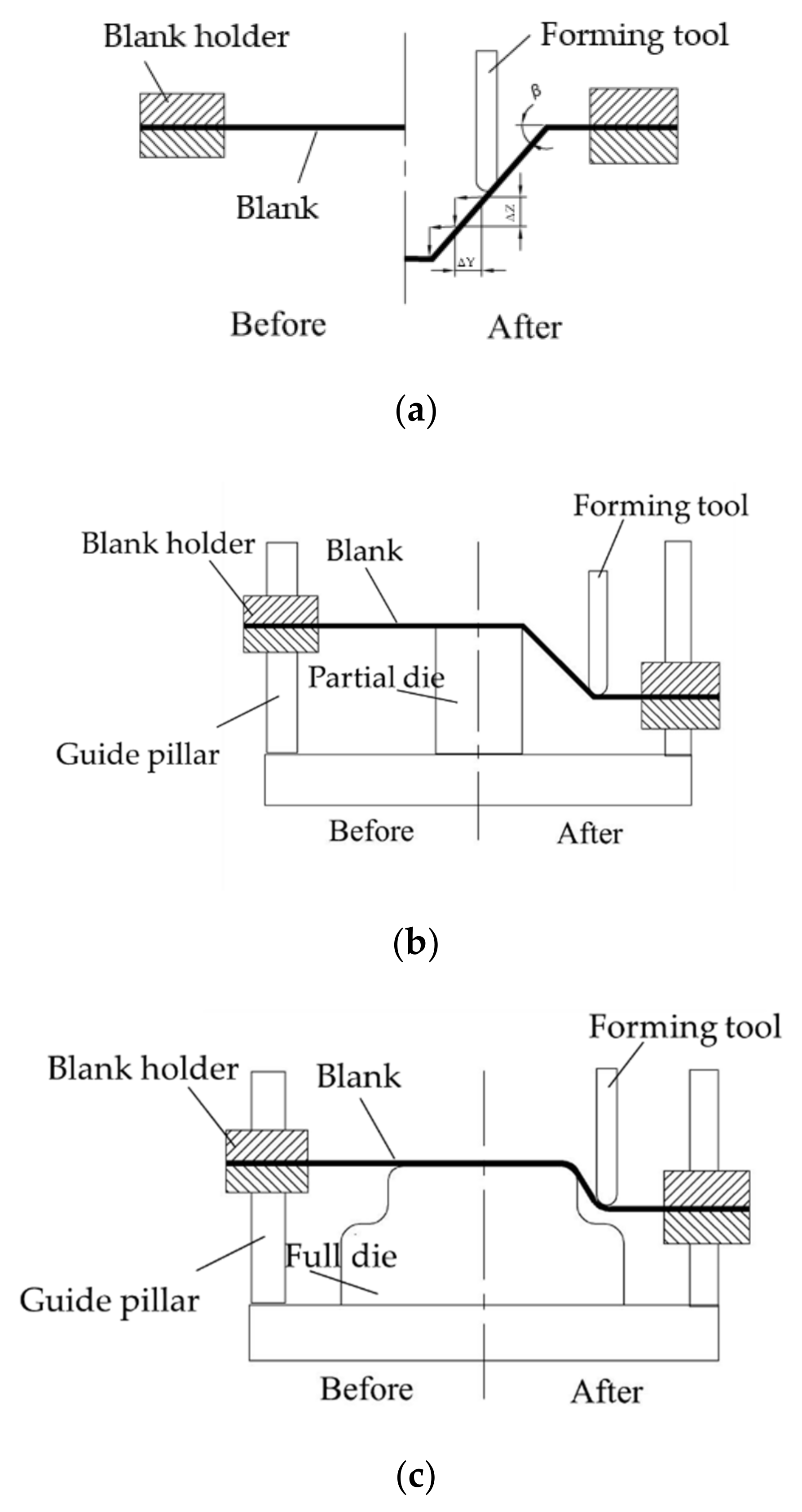

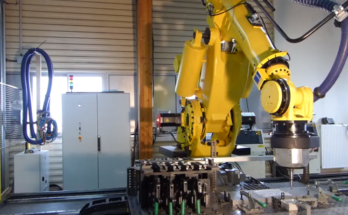

The tool which can be attached to a cnc machine a robot arm or similar indents into the sheet by about 1 mm and follows a contour for the desired part.

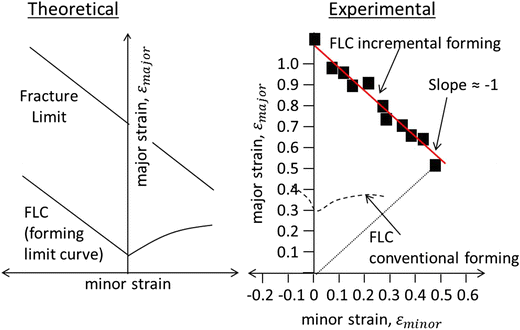

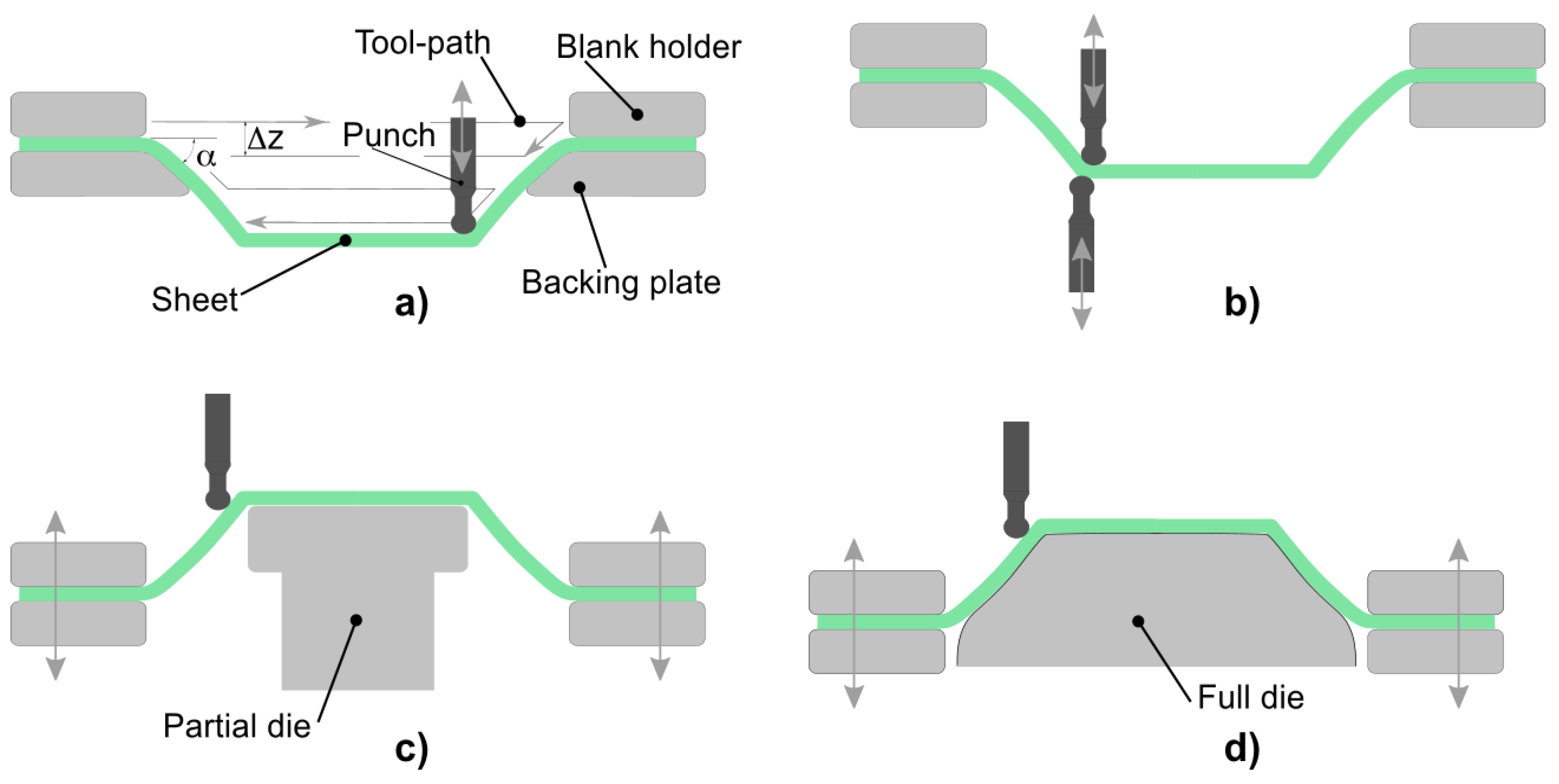

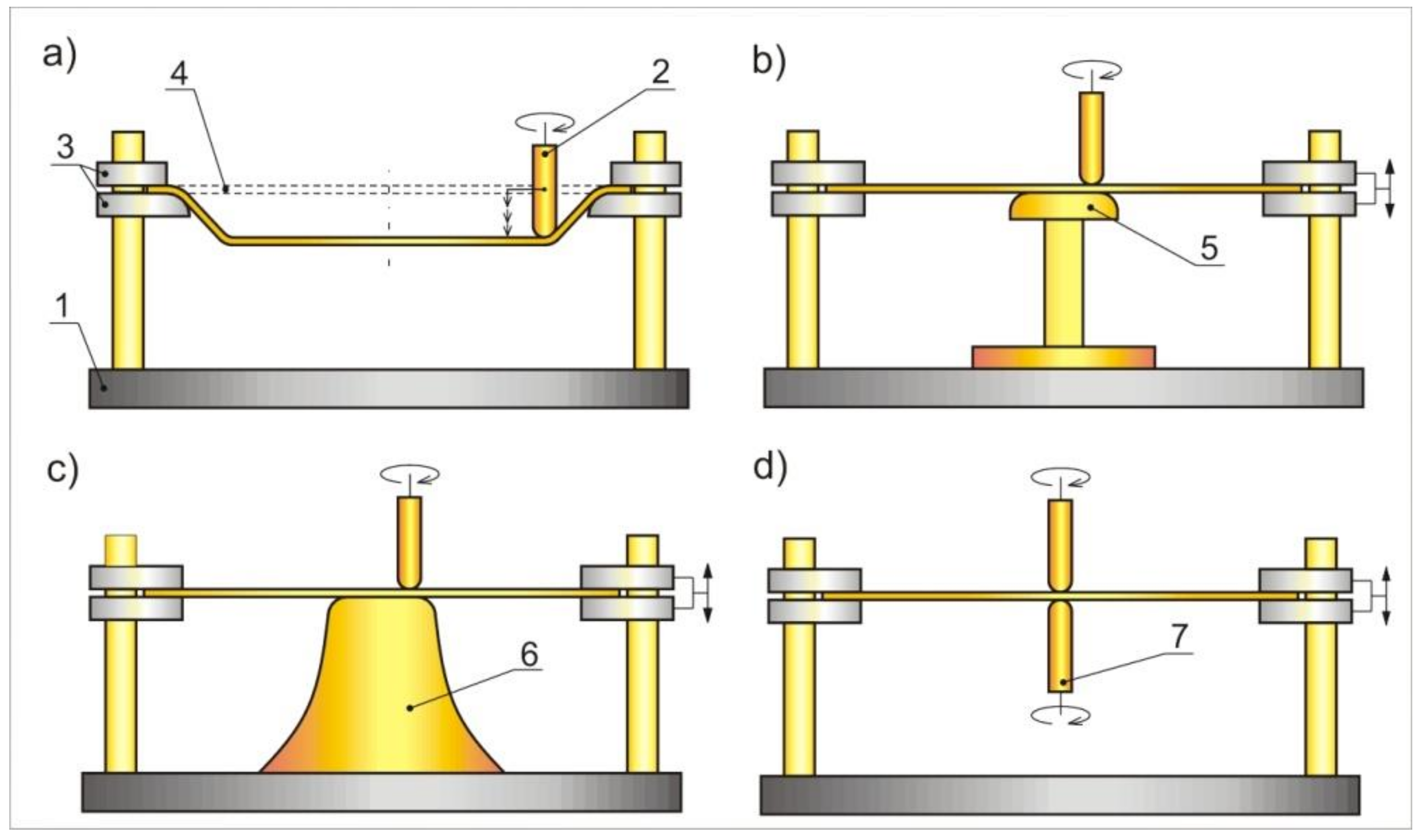

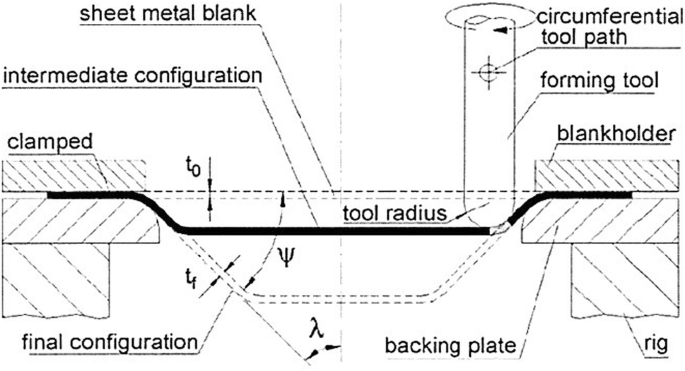

Fundamental studies on the incremental sheet metal forming technique. With this technique the forming limit curve flc appears in a different pattern revealing an enhanced formability compared to conventional forming techniques. In the sheet metal cnc incremental forming process the forming tool moves around the outline of the sheet metal part along the predefined toolpath and extrudes the sheet metal point by point and. Generally the sheet is formed by a round tipped tool typically 5 to 20mm in diameter. However studies have shown that it can be applied to polymer and composite sheets too.

In this paper inconel 718 a material that has extensive use in aircraft engines is considered for experimental work to obtain the optimum. The principle of nc incremental sheet metal forming process as well as the experiment of cone forming are presented. Incremental sheet forming is a sheet metal forming technique where a sheet is formed into the final workpiece by a series of small incremental deformations. Summary single point incremental forming spif is a sheet metal forming technique that is gradually evolving towards industrial applicability.

Fundamental investigations of the incremental sheet metal forming technique were performed in the present study. Generally the sheet is formed by a round tipped tool typically 5 to 20mm in diameter. In the present study the formability of an aluminum sheet under various forming conditions was assessed and difficult to form shapes were produced with the technique. Incremental sheet forming is a flexible and versatile process with a promising future in the batch production and prototyping sectors.

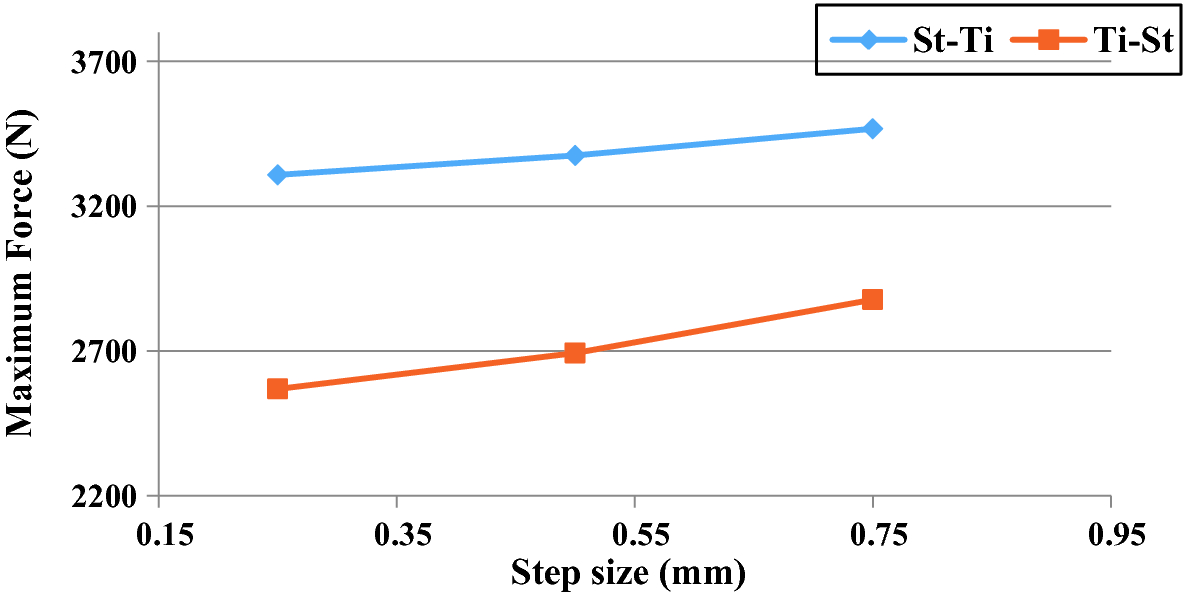

With decreased design time and negligible production time incremental sheet forming provides reliability flexibility and quality while being an economical option in contrast to the traditional forming process. Also conventional techniques such as stretching and deep drawing processes were simulated by a commercial fem package for the purpose of comparison in the aspect of forming capabilities. As recent market analysis studies have shown accuracy is one of the most important limiting factors for the deployment of spif in industrial applications. Because the deformation of sheet metal only occurs around the tool head and the deformed region is subjected to stretch deformation the deformed region of sheet metal thins and surface area increases.